What’s a Ducted Fume Hood ?

Many laboratories have ducted fume hoods installed. A chemical ducted fume hood is a significant safety device that is critical to maintaining acceptable laboratory air quality and preventing user exposure to potentially harmful chemicals. Yet, the fume hood is the most misunderstood and misused safety device in the laboratory. So much mystery and myth exist regarding how a fume hood works and how to use it safely. It starts with the perception that a ducted fume hood is a standalone device and if there is a ducted fume hood in your laboratory and you use it, you will be safe. The reality is that a ducted fume hood is only a small component in the mechanical ventilation system of a laboratory. It is the point of interface between the user and the laboratory ventilation system (LVS).

The ducted fume hood does very little alone. Yes, there are good hood designs and not so good hood designs, but until connected to a properly designed and maintained laboratory ventilation system, the ducted fume hood is just an enclosure that does nothing. The primary purpose of the fume hood is to protect users from exposure to harmful chemicals that are being used inside the hood. To do this, a fume hood must capture, contain, dilute, and exhaust those dangerous substances. None of this is possible without a ventilation system.

How to inspect a Ducted Fume Hood according to ASHRAE 110-2016 ?

Internationally, ASHRAE 110 is the standard use to inspect and evaluate the performance of a Ducted Fume Hood. According to ASHRAE 110-2016, three alternate ratings can be determined, depending on the condition of the test, namely AM, AI and AU

An “as manufactured” (AM) test would be conducted at the hood manufacturer’s location and would test only the design of the laboratory hood independent of the laboratory environment.

An “as installed” (AI) test would be conducted in a newly constructed or renovated laboratory after thorough testing and balancing has been completed but before the user has occupied the laboratory. Consequently, the test would include the influences of the laboratory environment, such as the aerodynamic design of the hood, the supply air system, the geometry of the room, and the exhaust air system.

An “as used” (AU) test in which the investigator accepts the hood in the condition in which the user has established the hood. This includes obstructions within the hood, maladjustment of the baffles, thermal challenge within the hood, and other factors.

There are three things that the tester is checking when performing a fume hood safety inspection: flow visualisation, face velocity, and tracer gas performance (Containment Test). The measuring scale is broken down into four ratings which are “fail, poor, fair and good” and of course the aim of the test is for the fume hood to rate “good” , which ensures laboratory safety and compliance.

Flow Visualization consists of two tests known as local smoke and gross smoke. These names are self-explanatory in that the tester utilises smoke to check for leaks, or cracks in the fume hood, structural defects, air flow inefficiency or other issues that may allow gas to escape. A smoke gun is used to perform this test but the gross smoke measurement is done on a macro level in which a smoke bomb is detonated in the middle of the fume hood. If any smoke escapes out of the front of the hood during either test, the fume hood will receive a “fail” rating and appropriate action must be taken to rectify it.

Face Velocity is the measurement of air flow through the fume hood. Different fume hoods have face velocity specifications for ventilating gases and it’s important that the fume hood maintain these levels. Otherwise, it’s considered compromised and unsafe. This test is performed with the sash open 25%, 50% and 100% using a device that measures air flow at different place within the hood. Those readings are then compared to the manufacturer’s specifications for that fume hood to ensure complete functionality.

The Tracer Gas SF6 test (Containment Test) is performed to check for leaks within the hood. A mannequin in placed in front of the hood in different places for five minutes at a time. The sash is opened and closed accordingly, and the data is collected using a probe attached to the mannequin. If the probe measures more than 0.05 ppm (parts per million) of tracer SF6 gas, the fume hood receives a “fail” rating.

For a laboratory to be considered “safe” the fume hood must function properly, efficiently, and safely, hence the testing. The fume hood is a machine, after all, and thus subject to the same level of wear and tear as any other manufactured product. Annual testing ensures that your fume hood is durable but, more importantly, that it’s safe to operate. The ASHRAE 110 test confirms this safety and guarantees compliance with governmental and industry standards.

Situation in Malaysia

According to Malaysia Standard MS 1042-7:2011, Safety in laboratories – Code of Practices Part 7 : Fume Cupboards. It does recommended flow visualisation, face velocity and tracer gas SF6 test. Unfortunately, there are no facility for Tracer Gas SF6 Test (Containment Test) available in Malaysia even after 10 years this standard has published. We urgently need a complete ASHRAE 110 compliance test facility in Malaysia that could provide AM, AI and AU service to the industries and laboratories to safeguard the safety of our laboratory users.

.

.

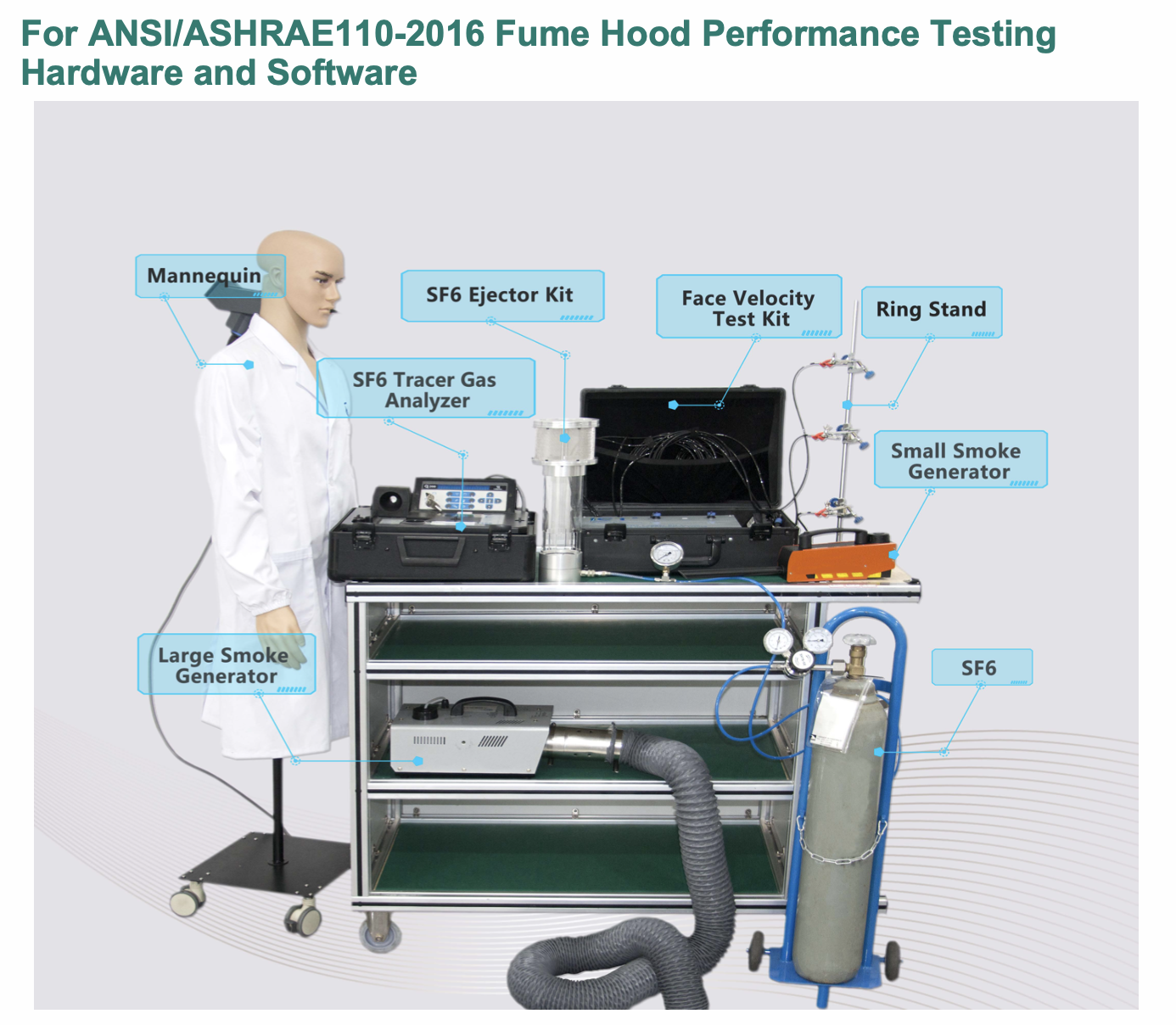

Setting Up ASHRAE 110 Inspection Facility with D-Industrial’s Complete Fume Hood ASHRAE 110-2016 Testing Set

D-Industrial Technology is the world leader in providing total solution for fume hood testing according to ANSI/ASHRAE 110-2016. The complete fume hood testing set consist of the following set up :

1. SF6 Tracer Gas Analyzer Q200

- The SF6 tracer gas analyzer Q200 uses advanced ECD sensing technology (originated from UK – AI Qualitek, technology been acquired by D-Industrial) and can detect at least 0.01ppm SF6.The Q200 response time (T90) is less than 1 second, and the reading can be stabilised at the maximum concentration in less than 2 seconds.

2. SF6 Ejector Kit

- The SF6 Ejector kit includes: SF6 ejector, calibrated critical orifice (release flow 4 L/min at 30 psi), special gas pressure regulator, pressure gauge (0 to 60 psi), and quick connector.

- The SF6 ejector is manufactured according to the ANSI/ASHRAE 110-2016-4.2 Ejector System.The Orifice was manufactured in accordance with the ANSI/ASHRAE 110-2016-4.3 Orifice parameters, and the release rate of SF6 was controlled to be 4 liters per minute (4 Lpm) at the pressure of 30 psi.

3. Face Velocity Test kit with data logging capability

- Four high precision air velocity transducer and high performance data logger are integrated. Through it, the face velocity of the fume hood can be tested quickly without interference, and the data can be automatically recorded, calculated and reported by special software.

4. Small Portable Smoke Generator

- The Smoke Generator is mainly used for visualisation test of fume hood. It includes a small smoke generator and a large smoke generator.

5. Large Volume Smoke Generator

- Equipped with 1000W high-power smoke generator and electronic thermostatic control system, it can continuously generate a large amount of white smoke

6. Manniquin Stand

- The mannequin kit includes a mannequin, a retractable support frame and a lab coat. The mannequin is compatible with the parameter requirements specified in ANSI/ASHRAE 110-2016.

7. Software for ASHRAE 110-2016

- Compatible with ANSI/ASHRAE 110-2016 Fume Hood Performance Test Program

- The test program includes Test Conditions, and Fume Hood Information Record, Cross Draft Test, Face Velocity Test, VAV Face Velocity Control Test, VAV Response and Steady Time, Flow Visualization Test, SF6 Tracer Gas Tests.

TMS is appointed as exclusive agent by D-Industrial in Malaysia. TMS is capable to set up the complete ASHRAE 110 Testing Facility. We are able to work in term of turn-key basis or act as testing devices provider. We aim at upgrading the laboratory fume hood quality in Malaysia and this region, by helping the government agencies, universities and testing laboratory to setting up this world class, ASHRAE 110 compliance test facility.

Do reach out to us for more information, email to joseph@tms-lab.com

More information about the Complete ASHRAE Test Set